CHALLENGE

Installing track panels has traditionally required a two-step process: rough adjustment followed by fine adjustment. This method is time-consuming and labor-intensive, especially in tunnel settings where space is limited. The need for precise alignment of track panels adds to the complexity, often causing delays and increasing labor costs.

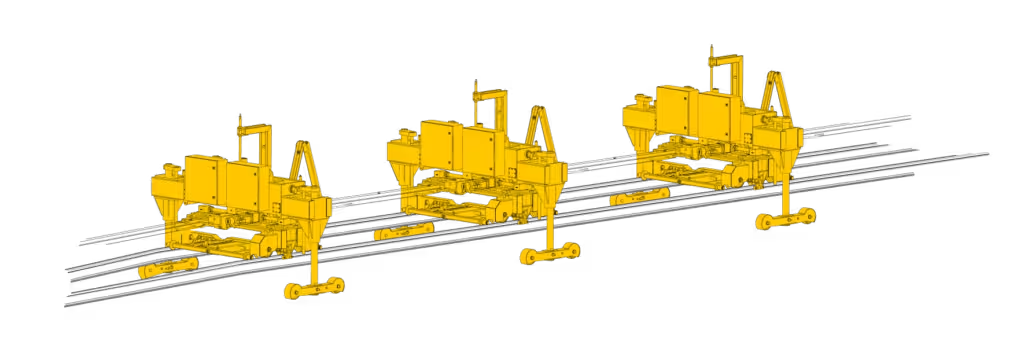

SOLUTION

The Track Adjustment Machine (TAM) simplifies the installation process by combining lifting and precise alignment into one step. It can handle up to 500 meters of connected track panels in one go, adjusting them both vertically and horizontally with an accuracy of +/- 1 mm. TAM is particularly useful in tunnels, where its ability to fine-tune track placement quickly and efficiently reduces labor and speeds up the process. With an 80 kW power generator and the capacity to lift up to 3 tons, TAM can adjust track panels with ease. It only requires seven people to operate: one operator, four to adjust spindles, and two to measure, improving efficiency significantly.

STRAIGHT TRACK PERFORMANCE

240m/day

CURVED TRACK (150 mm cant) PERFORMANCE

154m/day

TECHNICAL SPECIFICATIONS

TRACK

ALIGNMENT MACHINE

- Generating Power: 80 kW

- Vertical Lift Distance: 400 mm

- Horizontal Adjusting Range: 200 mm

- Transversal Slope (Cant) Adjusting Range: 160 mm

- Max. Adjusting Tolerance: ± 1 mm (1435 mm gage)