RAILONE GERMANY, China

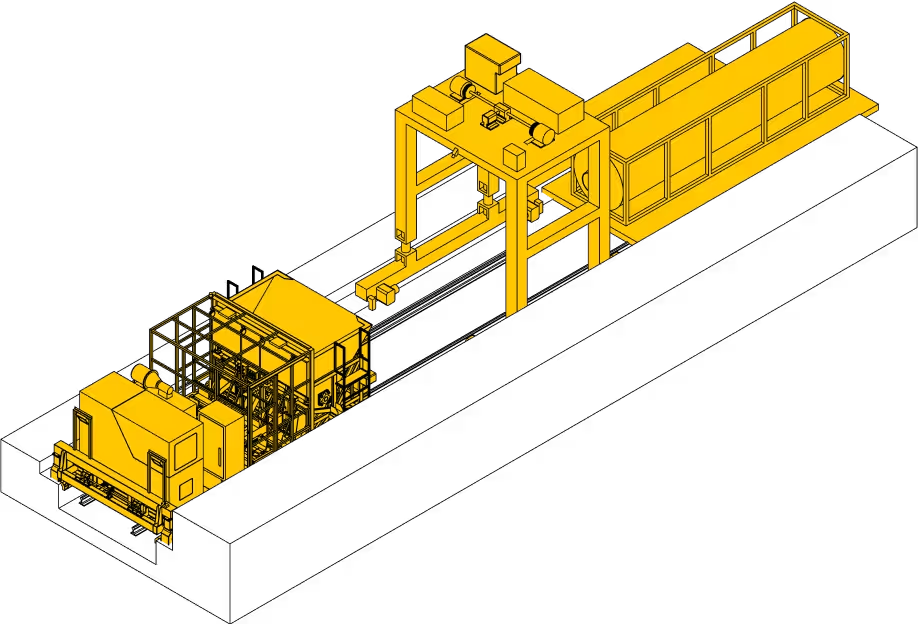

CPM – Concrete placing machine

Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took.

· Richard

, CEO RAILONE

CHALLENGE

Improving the quality and efficiency of concrete placement in construction is essential, but traditional methods can be slow and labor-intensive. The process typically involves transporting and pouring concrete manually or with basic machinery, which often results in inconsistent quality and delays. Additionally, it can be difficult to manage precise pouring in large-scale projects, especially in confined areas like tunnels.

SOLUTION

The concrete placing machine addresses these challenges by streamlining the entire process. It consists of several key units, all mounted on a self-propelled vehicle that runs along a track. The machine includes a 4m³ buffer concrete hopper, a track pouring unit with feeders and vibrators, and an electric/hydraulic power unit for self-propulsion. Concrete is transported from the tunnel entrance in 4m³ tanks via a flatbed rail car. These tanks are then transferred to the placing machine by a gantry crane.

Once in the machine’s hopper, the concrete is fed to four dispensers, each equipped with vibrators to ensure even pouring. The machine runs on hydraulic power, using six hydraulic drive wheels and six non-brake wheels, making it highly efficient for large-scale concrete placement.